The conurbation between German cities Duisburg, Dortmund and Muenster is one of Europe’s most densely populated areas. Without thinking much about it, five million people in this area use water every day and rely on a well-functioning wastewater disposal system. For more than 100 years, two German water management associations called Emschergenossenschaft and Lippeverband (EGLV) have been ensuring exactly this.

In order to keep an eye on and monitor all of the 750 operating facilities, EGLV’s new headquarters in Bottrop, Germany, rely on KVM products from G&D.

The Ruhr area, Germany’s most populous region, is known for its focus on mining, which led to mining-related subsidence in large parts of the region. Thus, many areas of land are located below the water level of the rivers Lippe and Emscher. Smoothing out these subsidences required the construction of high dikes. Due to these difficult conditions, reliable pumping stations are indispensable in this region.

In order to centrally monitor these pumping stations, but also other operating facilities such as rainwater treatment and sewage treatment plants, EGLV built a new operational monitoring centre in Bottrop, Germany. To monitor the systems of this new centre, the EGLV team rely on KVM equipment from G&D

“G&D’s on-site and technical support during the installation of the systems has been very helpful.” (EGLV)

Solution and technical implementation

The countless monitors and large screens immediately catch the eye as soon as you enter the new monitoring centre. The control room includes three state-of-the-art workstations with up to ten monitors, without even considering the large screens. From here, all EGLV operating systems are centrally monitored. And monitoring these systems is absolutely necessary, since every day up to 180,000 reports arrive at the monitoring centre.

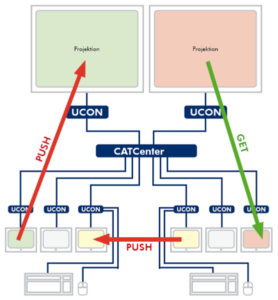

In order to make the work of the control room staff as simple, intuitive and user-friendly as possible, the computers were removed into a central server room. From here, a KVM matrix switch DVICenter DP64 transmits their signals to the control room. Thus, all three workstations have access to all computers stored in the server room. With the help of DVI-CON user modules, the EGLV team can still operate the remote computers as if they were located under their desks.

TS function and CrossDisplay-Switching lead to integrated workstation

With the TS function of the matrix, multi-monitor workstations are easily transformed into an integrated workstation that can be operated with just one mouse and one keyboard.

The integrated CrossDisplay-Switching also switches keyboard and mouse signals. When moving the cursor from the active to an inactive display, the keyboard-mouse focus automatically switches to the connected computer. TS LEDs continuously show operators the currently active computer-monitor constellation. As extension of the workstations, the large screens in the operations monitoring centre are also integrated in the CrossDisplay-Switching function.

Optimised team work

In order to optimise the collaboration in the control room, EGLV use the Push-Get function integrated in the DVICenter. With this function, users can move the screen contents of a target to (push) – or get it from – the display of another console. This display can be a large screen projection, for example. By using this function, control room operators can work together on solving issues. “Events such as floods can now be handled by the team. Thus, one facility can be displayed on all three workstations. In an emergency, even the employees of the wastewater treatment plant can access the systems for monitoring operations and vice versa,” says Christian Stratmann, Head of the Communications Team at Emschergenossenschaft und Lippeverband.

The functions in use already make the daily work of the EGLV staff a lot easier. But EGLV still have plans for further expansions. In a next step, they plan to use SNMP to monitor their systems in order to ensure that all KVM components are operating properly. The monitored values are sent as SNMP trap and are then made available to the technical personnel. The technicians can use SNMP-GET to query values and thus monitor the system conditions of the KVM devices and the connected peripherals.

“Reliability was and still is extremely important to us. That’s why we G&D’s equipment has been the perfect choice.” (EGLV)

Server room – clearly-arranged and air-conditioned

Thanks to G&D’s KVM devices, the air-conditioned server room also looks tidy and clearly arranged. Here too, special attention was paid to creating optimal conditions for the equipment since powerful processors generate a lot of waste heat and require intensive cooling.

The server rack houses the matrix switch DVICenter DP64, several CPU modules as well as three MultiPower devices for the central power supply of the computer modules. From here, CAT cables extend the computer signals into the control room. Of course, wiring a project such as the operational monitoring centre in Bottrop requires vast lengths of cables – in this case even 450 kilometres, the distance between German cities Hamburg and Bonn.

Outlook for future challenges

Today, hardly a day goes by without the media reporting on extreme weather events. Therefore, EGLV will certainly be faced many new challenges in the future. In addition, the Emschergenossenschaft is currently working on the reconstruction of the river Emscher with the aim of transforming it back into a near-natural river. For this purpose, new sewer tunnels and pumping stations will be built so that in the future the region’s waste water can be disposed of underground. The pumping stations, for example, will also be monitored from the central control room in Bottrop.

Tl;dr? Here are the most important facts of the EGLV project:

Customer

Emschergenossenschaft and Lippeverband (EGLV) are two water management associations under public law and Germany’s largest wastewater disposal company and operator of sewage treatment plants.

Challenge

- Monitoring of 750 facilities at one location

- High demands with respect to safety and productivity

Products in use

- DVICenter DP64

- DVI-CPU-UC

- DVI-FiberLink

- DVI-CON

- TS LEDs

- MultiPower

- programmable input devices

Result & benefits

- Concept for a complex operations monitoring centre

- Clearly-arranged workstations without the need for many keyboard and mouse devices

- Optimised team work

- Sophisticated rights administration for different groups of employees

- Clearly-arranged and air-conditioned server room

- Trade shows 2023: Experience G&D KVM products live and up close - 11. January 2023

- Innovative KVM solutions for control rooms - 14. December 2022

- Ada Lovelace – a true visionary and the world’s first female programmer - 12. December 2022

One thought on “Wastewater treatment with KVM from G&D? This is how it works”